Underground & Above Ground Storage Tank Inspections & Testing

Non – Volumetric Tank Tightness Test

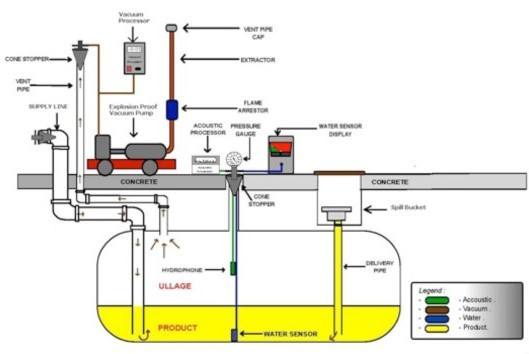

Satisfying DEC/EPA mandated tightness tests, our experienced team is proficient in underground and aboveground storage tanks up to 30,000 gallons with a Leak rate of 0.1 gph with PD + 100% and PFA + 1.6%. We verify the main and interstitial storage areas and handle tanks of varying sizes, ages, and applications, including those containing gasoline, aviation fuel, diesel, fuel oil #4, waste oil, and more.

Pressurized Line and Leak Detector Testing

Annual pressure tests are often required for fuel stations with underground pressurized supply lines. Our factory-trained professionals are certified to test for leakage as well as the functionality of associated lines. Handling a variety of applications and fuel types, we provide exceptional precision and accuracy. Depending on line size, temperature and sit conditions, testing is typically completed in 30 minutes per line.

New EPA Regulation 40CFR, part 280, Requires underground storage tanks to perform annual and triennial testing / inspections on your tanks associated equipment, Starting in 2018. We offer all these test and inspections so your site can comply with New York State DEC and EPA standards.

Release Detection Equipment Testing

Annual Automatic Tank Gauge Inspection is necessary to comply with EPA Regulation 40 CFR, part 280 and covers the console, inventory probes, contact sensors, and alarms. Our procedures verify that the equipment is operating properly, identify concerns and with factory parts readily available, provide repairs, and guarantee passing results.

Cathodic Protection Testing

Cathodic protection combats corrosion on the underground storage tank. Electrical current supplied from an alternate source converts all the anodic sites on the metal to the cathodic sites. Typically, this takes the form of galvanic anodes. Through annual testing, we confirm these anodes remain in peak working condition.

Spill Prevention Equipment Testing

We perform triennial inspection and testing of the UST’s spill pumps to confirm the absence of leaks and prevent contamination of the surrounding ground.

Precision Hydro-Static Containment Sump Testing

Triennial inspection and hydrostatic testing of the USTs STP containment and transfer pumps are performed to detect possible leaks and protect against contamination of the ground around it.

Overfill Prevention Equipment Testing

To ensure that the tank cannot fill past 95% capacity when receiving a fuel delivery, we complete a functionality inspection of the USTs auto limiter shut off valve located in the tank’s fill tube.